Understanding the TEC

The Freezone Elite system is very small for an organised watercooling set up, but CoolIT claims that the unit can dissipate up to a whopping 250 watts of heat. Yep, that's right, two hundred and fifty watts. That's roughly twice the TDP of Intel's latest flagship quad-core processor.How does it do it? With a little help from a technology that many of you maybe familiar with: Thermo-Electric Cooling, aka TECs or Peltiers.

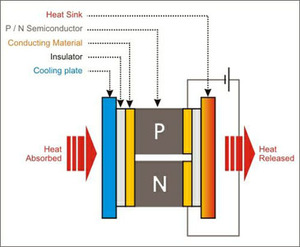

A TEC is a very handy and powerful lovechild of physics and chemistry. It consists of nothing more than a set of plates separated by two semiconducting metals. By passing an electric current over one of the plates, a field is created that pulls the heat from the other side. This creates a pump, where the "cold" side draws heat from contacting surfaces and the "hot" side expels heat to contacting surfaces.

So, if you slap what you want chilled on the "cold" side and a heatsink or other distribution method on the "hot" side, you create an active heat transfer is incredibly effective. The higher the current, the better the temperature gradient that can be sustained (and therefore more heat can be moved).

The idea of Peltier cooling is usually reserved for more "extreme" enthusiasts, as it's fraught with some rather difficult problems. First of all, unlike water, a TEC can lower temperatures below ambient, meaning that it is possible for condensation to occur on the cold side of the plate. This means that if your TEC is directly over your CPU, it can have disastrous effects. Second, Peltier cooling is active, and thus requires power – the more heat that must be moved over a small space, the more power it requires.

A diagram of a Peltier system.

PWM is the preferred method, as it means you don't have to have huge capacitors and resistors and various other things to try to control relatively massive amounts of current (we're talking of about 75w for an effective CPU cooling unit – almost as much as the CPU itself). If you only need a four to five degree temperature gradient instead of a 20 degree gradient, you turn the power on and off so that the overall current is only 25 percent of capacity. Thus, you don't need to have analogue step-up and step-down methods – simply a gate that lets the same current through only 25 percent of the time.

Here again, we enter into yet another problem. Controlling current in this way generates other electromagnetic fields that can have a huge effect on more delicate transistor-based electronics that are in close proximity... like your CPU. What does that all mean? Well, statistically, it means that whenever your peltier is running between about 25-75 percent of its maximum potential on a PWM circuit, your computer will likely crash.

And that is why Peltiers are usually more "extreme" systems – because to work for our needs, they have to be fairly powerful and always on, meaning that it involves pretty much the same preparation of neoprene, silicon and sealing agents that evaporative and phase-change cooling require.

Fortunately, the guys at CoolIT had a little different idea...

Practical implementation

You can see one of the large blue groups of TEC plates

on the top of the radiator - a second is on the underside.

CoolIT has moved the TEC units to the radiator assembly to avoid all of the above problems. First, the units themselves can be much bigger since they don't have the same space requirements as a CPU block would. Since contact area is an integral part of cooling efficiency, larger plates mean that the overall temperature gradient doesn't need to be as large. This, in turn, means that power requirements can be much lower. And since the TEC plates aren't right over the CPU, the much-reduced EMF interference from using PWM for power regulation is not a problem.

In the Freezone Elite, we find a totally climate controlled micro-sized watercooling loop. A tiny pump circulates a cooling fluid to the CPU block, where the fluid picks up heat. It then brings the heated fluid back to the radiator, where the TEC plates actively pump out the heat to the fin assembly, where it is exhausted by the 120mm fan on the back. This whole process moves heat a lot more quickly and effectively than a traditional radiator in a standard watercooling setup.

All of this is controlled by the MTEC controller, which is (essentially) the PWM relay. It reads the temperature of the fluid inside the unit and powers the TECs and the fan to a level that appropriately cools that fluid to a target temperature. Through the USB interface on the controller, desired temperatures and/or power requirements can be set using the included software.

It sounds brilliant, cool, and effective. But does it work?

MSI MPG Velox 100R Chassis Review

October 14 2021 | 15:04

Want to comment? Please log in.